CNC Countertop Machine

INTRODUCTION

When your company make countertops, we believe this machine will be perfectly in compliance with your needs, and achieve high manufacturing efficiency. It well works for granite, marble, quartz or other natural stones.

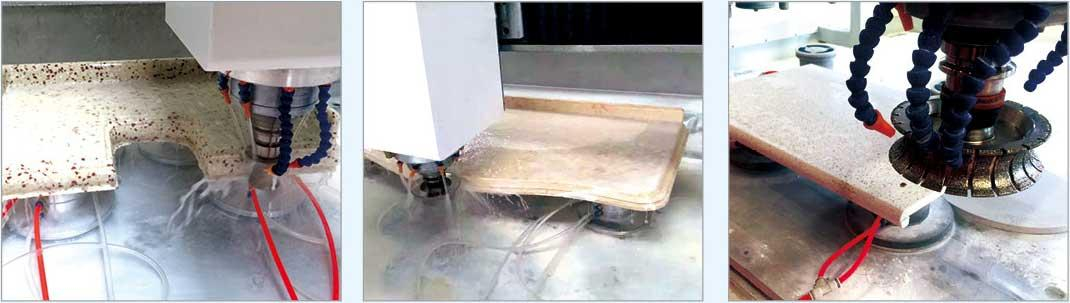

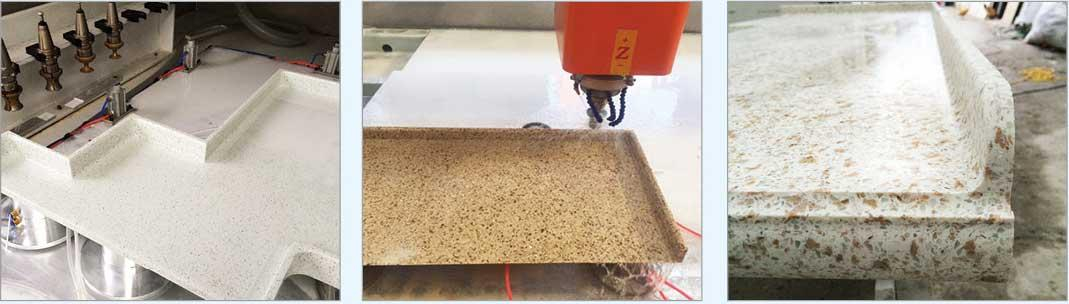

Machine has 18 tools storage ,it can meet any complex countertop fabrication works. ATC system makes the whole process of hole drilling, basin milling, edge grinding processes in a high degree of automation.

Operations of the machine not complicated. this cnc machine is drive by smart controlling software, first you need design the patterns with CAD software, then input the CAD drawing to System and set parameters. The System can work out the best route and generate code. Thirdly copy the codes to the computer. The computer will read the codes and transfer to machine, then the machine will start to work automatically and finish whole countertops manufacturing. Including automatical tools change.

Main spindle driven by 11kw servo motor, gives strong power to cut hard stones.

With suction cups to fix slab material ensure precision processing .

Mechanical body and gantry structure, high quality steel welded and tempered to ensure machine long lifespan and without deformation.

Adopt famous and top brands brands components to ensure stability and quality, such as Yaskawa drive motor and drive for high speed ans precision, Omron switch for protection. auto lubrication pump. Automatic Oiling System.

Two standard models available, MTYK-3015 with maximum working size 3000X1500mm, MTYK-3215 with maximum working size 3200X1500mm.

Machine with main functions as below:

1. Grind and polish stone sink hole and edge.

2. Rear Waterproof Round Bottom Processing

3. Cut stone countertops sinks

Technical data

|

Model |

MTYK-3015 |

MTYK-3215 |

|

X Working Area |

3000mm |

3200mm |

|

Y Working Area |

1500mm |

1500mm |

|

Z Working Area |

300mm |

|

|

Re-Positioning Accuracy |

±0.02mm |

|

|

Table Surface |

Aluminum plate |

|

|

X,Y ,Z Structure |

Square guide rail for XYZ axis |

|

|

Max. Power Consumption |

2kw |

|

|

Max. Rapid Travel Rate |

70000mm/min |

|

|

Max. Working Speed |

25000mm/min |

|

|

Spindle Power |

11kw ATC Mechanical Spindle |

|

|

Spindle Speed |

0-8000 rpm / min |

|

|

Drive Motor |

JAPAN YASKAWA Driver & Motor |

|

| Inverter |

7.5kw Fuling Inverter |

|

| Command |

G-code*.u00*.mmg*.plt |

|

| Working voltage |

AC380V / 50Hz |

|

|

Control System |

Weihong |

|

| Limit switch |

Japan Omron |

|

| Oiling system |

Automatic |

|

| Package |

4100*2650*2000mm |

43000*2650*2000mm |

| N.W/G.W |

4500 KGS |

4800kgs |