Low price for 3 Inch Polishing Pads - Manual Polishing Machine – MACTOTEC

Low price for 3 Inch Polishing Pads - Manual Polishing Machine – MACTOTEC Detail:

INTRODUCTION

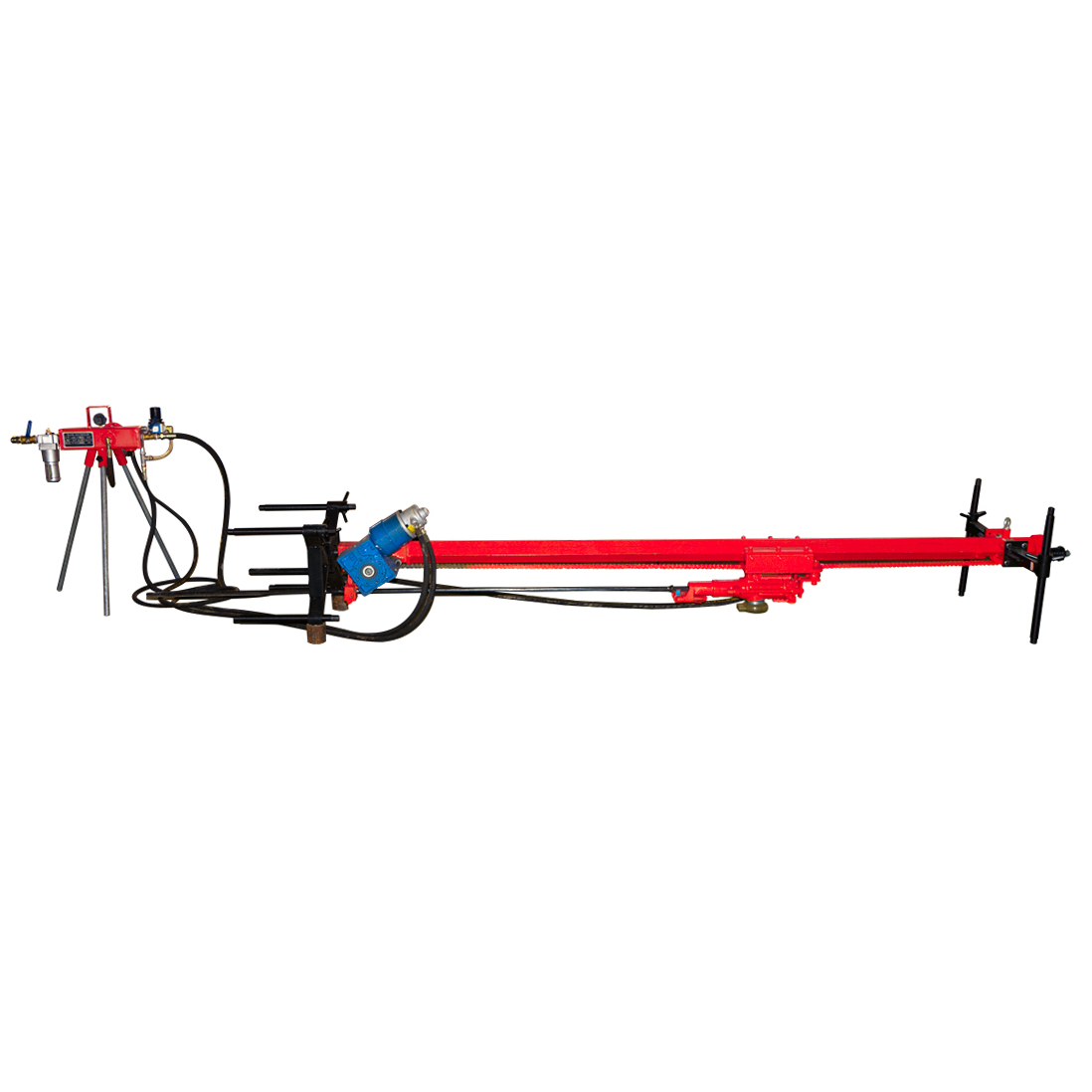

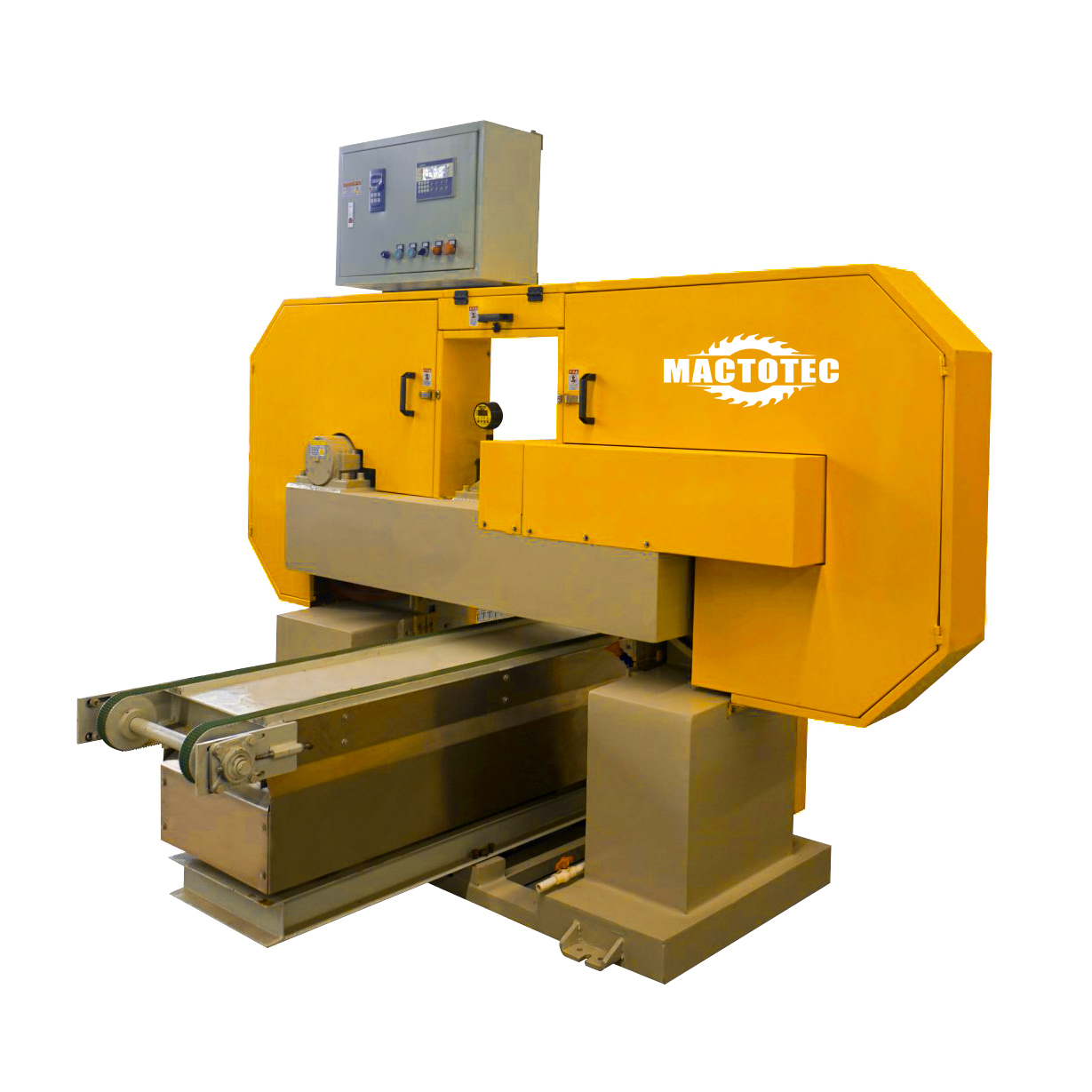

MTCZ-2800 Manual Polishing Machine is a equipment that need operator manually move the head of machine to polish and grind the stone. It suitable for the surface grinding and polishing of marble,granite, or other stone materials. for slabs, tombstone.

Machine structure is composed of the following parts: Main body up-down system, Principal axis grinding system,Principal axis up-down system,Rocker arm rotation part

Manual stone polishing machine can works on thickness from 10mm to 450mm. The arm moves up and down and driven by a motor. Handler of grinder 360° free rotating, moving semi-automatically and manually. The rotation is smooth and flexible; the grinding area can be up to 2m2, the production efficiency is 1.5~2m2/h.

The maximum processing size can be 2800mm length X 800mm width .

Operation of the machine is very easy. Place the stone material on cement table which under polishing range, start the motor, move the armrest to make polishing head well processed on stone. Stone material brightness after polished can reach 75-95 degrees.

This machine is economical in price which requires less investment. and land occupation is small which saves workshop space.

Machine adopts electric powered up-down, the flexible and stable rocker arm rotation conducted by 2 turning joints. The spindle grinding system drives the grinding wheel to rotate by long spline transmission and long key coupling, thus achieving grinding motion. The grinding and pressing system is used for grinding pressure and pressure adjustment by compression spring, ratchet, a pawl and locking mechanism.

Main shaft of manual stone polishing machine is fixed and installed in bore of fore arm wool shaft through the bearing, with this special design it avoid sliding, so that the main shaft runs stable, reduces vibration, noise and prolong service life.

Top quality manual polishing machine need top quality polishing tools to guarantee the working performance. Polishing tools replacing on this manual machine is easy . Mactotec also provide customers with various stone polishing tools in fantastic quality and competitive price.

Technical data

Product detail pictures:

Related Product Guide:

Excellent 1st,and Client Supreme is our guideline to deliver the ideal provider to our prospects.Nowadays, we have been seeking our to become certainly one of effective exporters in our discipline to meet shoppers more require for Low price for 3 Inch Polishing Pads - Manual Polishing Machine – MACTOTEC , The product will supply to all over the world, such as: Brasilia, Dominica, Brisbane, With the high quality solutions, excellent service, fast delivery and the lower price, we've won highly praise foreign customers'. Our products have been exported to Africa, the Middle East, Southeast Asia and other regions.

It is really lucky to meet such a good supplier, this is our satisfied cooperation, I think we will work again!