Automatic Edge Profile &Polishing Machine

INTRODUCTION

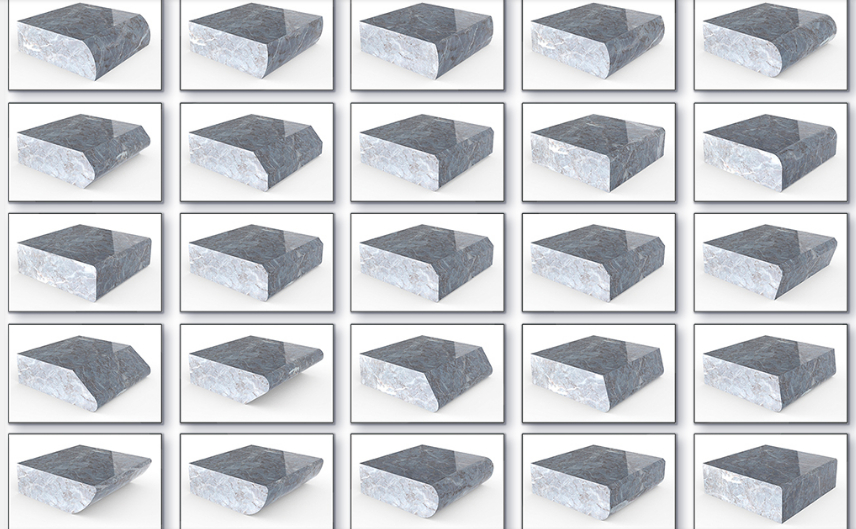

This machine is continuous processing line designed for fully automatic edge profiling and polishing for marble, granite, artificial stone, ceramic, glass,etc. the processed edge shapes including: full bullnose, haft bullnose, demi bullnose, pencil edge, ogee edge, chamfer, flat edge, crescent edge, double thick edge, 1/8” round edge,3/8” round edge, 3/16” round edge, 1/8” bevel edge, 1/4” bevel edge, 3/8” bevel edge, dupont edge, rock pitch edge etc.

The polishing part adopts PLC automatic control, from rough grinding to fine grinding finish automatically in one time , it greatly improve efficiency, save labor cost and achieves good brightness.

For this horizontal type edge polisher, we have 6 polishing heads and 8 polishing heads for your optional , the first head normally use sintering wheel, second and third heads use brazing or electroplating wheels, the following rest heads use resin polishing wheels and sponge polishing wheels.

Each of polishing head individual controlled. If you would like stop some of the polishing heads, you can off the switch of corresponding heads.

Edge polishing machine maximum working width 2000mm, maximum working thickness 80mm.

Special pressing rollers are designed to make sure the workpieces are tightly and accurately fixed and positioned to get a good quality profiling with high precision.

Easy and convenient tools installing, time-saving.

With wheel shaft of 30mm diameter, the most common dimension in the market, easy for tool matching.

Simple but precise wheel alignment (tool setting), high accuracy guaranteed.

Constant pressure self-compensation system ensures a high -quality product with high precision and uniform gloss.

Automatic shortage alarming &suspending function to prevent machine from damaging.

Conveyor self-cleaning and stone chip removing system.

Technical data

| Model |

|

MT6E-80 |

MT8E-80 |

| Heads Quantity |

pcs |

6 |

8 |

| Max Processing Width |

mm |

2000 |

2000 |

| Max Processing Thickness |

mm |

80 |

80 |

| Diameter of Profile Wheel |

mm |

140-200 |

140-200 |

| Diameter of Polishing Wheel |

mm |

160-200 |

160-200 |

| Main Power Supply |

kw |

3kw*6 |

4kw*8 |

| Water Consumption |

L/min |

100 |

100 |

| Processing Speed |

m/min |

0.2-2.2 |

0.2-2.2 |

| Overall Dimension |

mm |

3600*1100*2200 |

4500*1900*2200 |

| Weight |

kgs |

3500 |

4300 |