Curbstone Production Line

INTRODUCTION

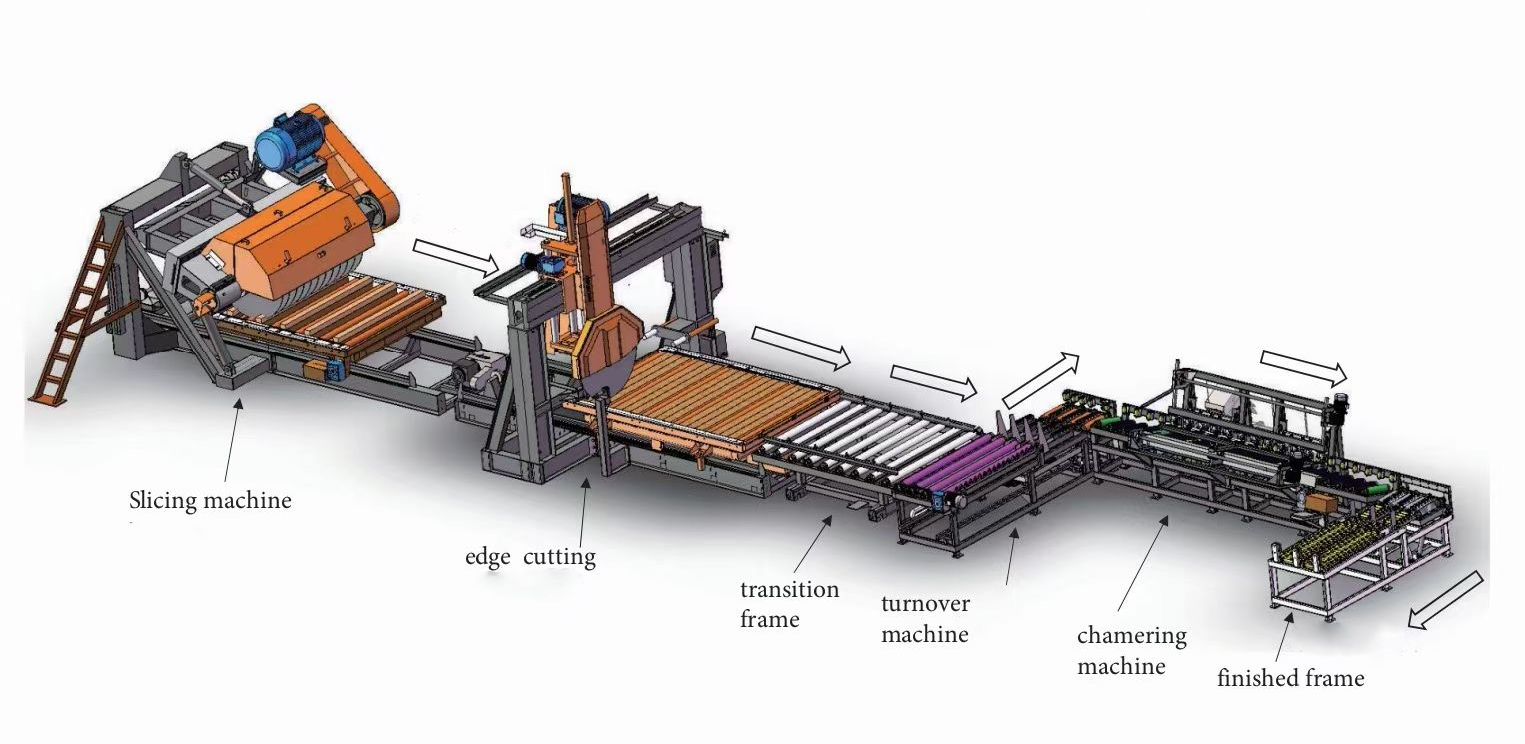

The whole curbstone production line consist of MTDF-1200-14 multi blades slicing machine, MTDF-1200-1 edge cutting machine and MTDF-400 chamfering machine. Popular used for kerbstone, roadside stone, cobblestone and tombstone producing .With rails and conveying trolleys which helps to realize fully automatic production, cutting and chamfering can be completed at one time,with advantages of high production efficiency , low labor investing and workshop space saving.

Curbstone production line with conveying rollers to transfer stones and sensors for automatic stop and operation. whole machine line only need one worker to manage it, realize high automatic production and save labour cost for stone manufacturers. Compared to cut curbstones by bridge block cutting machine, this line can save the steps of material loading and unloading,, reduce the need for forklift moving stones. Also improve the production safety.

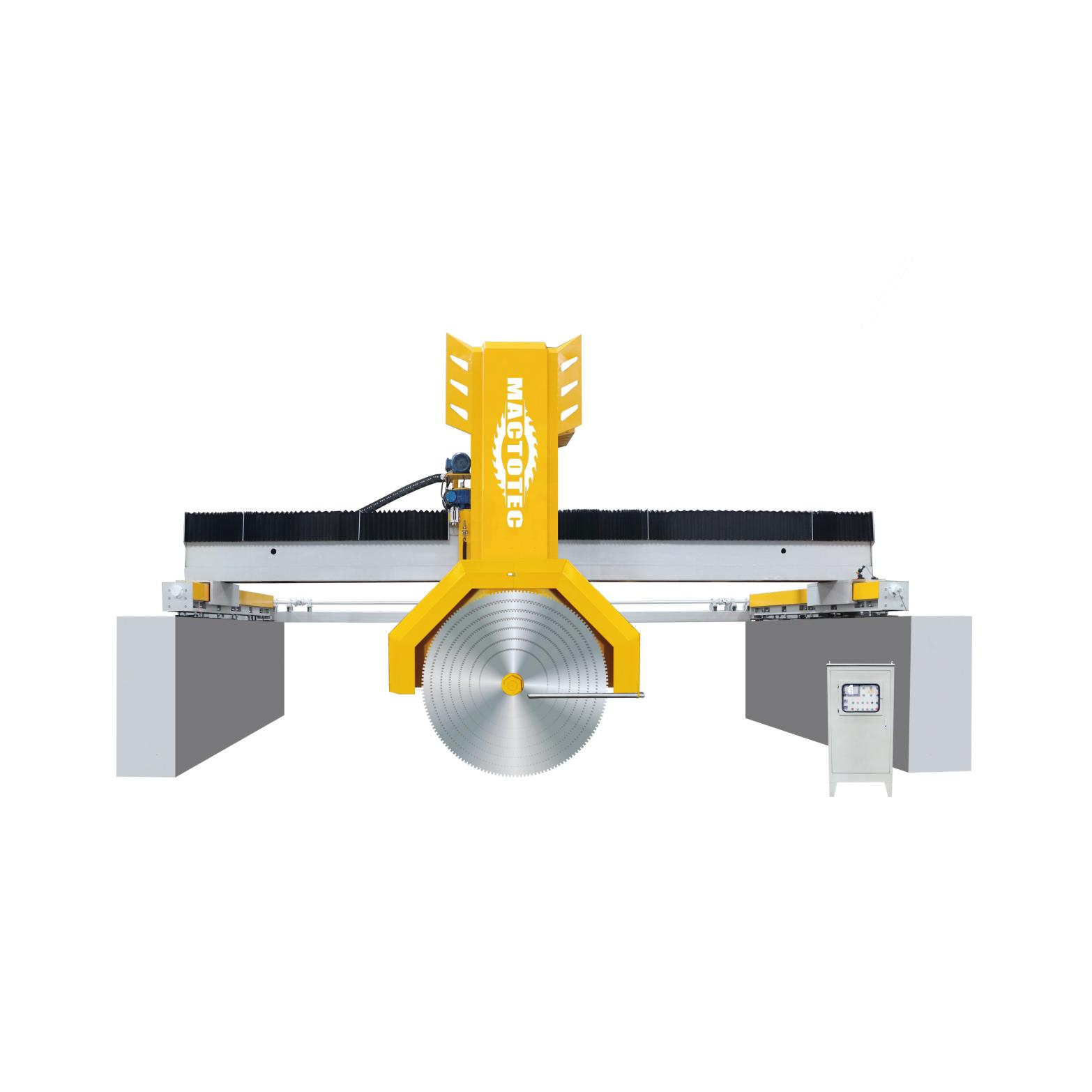

MTDF-1200-14 and MTDF-1200-1 curbstone cutting machines maximum cutting thickness can reach 45cm. MTDF-1200-14 Multi blades slicing machine can place 1200mm blades and cut with 14pcs of blades at the same time which significantly increase cutting efficiency and capacity, with producing output about 30-35m³/24h. Slicing machine equip with 55kw strong power motor, main spindle and a vice spindle sealing all saw blades together, in this way it can better ensure machine stability while cutting hard granite.

Machine build with high quality Cast iron to make the machine more stable with less chance of vibration under the continuous working condition.

Machine equipped with remote control , worker can manage operation through both controlling panel or remote control.

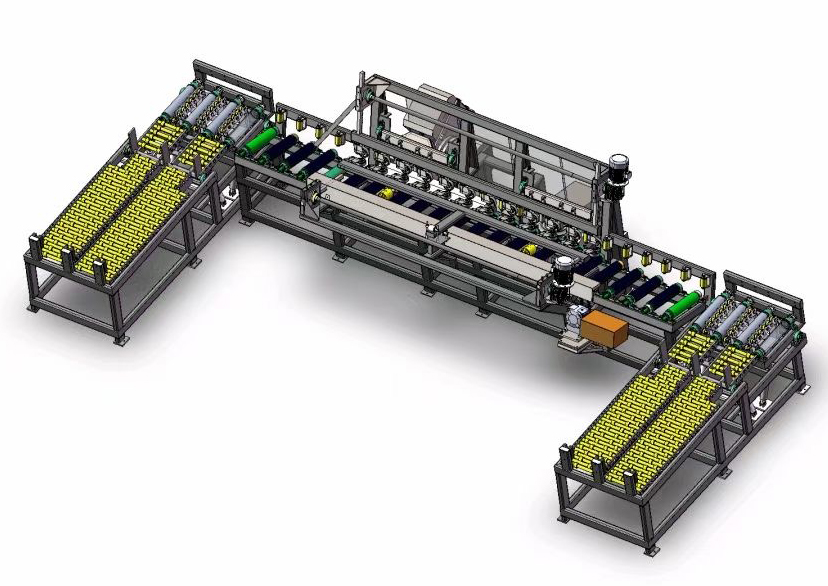

Chamfering machine is chamfered with water, effectively reduce dust and improves the production environment, and reduces the harm to workers.

The chamfering speed of the equipment is adjustable,

the chamfering size of automatic chamfering equipment is 10-50mm, which can be adjusted freely according to your precise processing requirement.

There is no need build cement foundation for this production line , easy for installation and save shipment space. whole line takes about 80 square meters only.

Technical Data

| Model | MTDF-1200-14 | MTDF-1200-1 |

| Dimension | 5800*3500*2500mm | 5800*3500*2800mm |

| Weight | 10T | 9T |

| Max cutting thickness | 450mm | 450mm |

| Worktable Size | 2500*1800mm | 2500*1800mm |

| Max stroke | 600mm | 600mm |

| Max cutting width | 1800mm | 1800mm |

| Main motor power | 55kw-6 | 22kw-6 |

| Max blades number | 14 PCS | 1 PC |

| Spindle diameter | 120mm | 50mm |

| Blades diameter | 1200mm | 1200mm |

| Water consumption | 20m³/hour | |

Technical Data

| Model | MTDF-400 |

| Blade diameter | 350/400mm |

| Chamfering size | 10-50mm |

| Main motor power | 11+11kw |

| Dimension | 7000*3000*1500mm |

| Weight | 5T |